| |

Cleaning |

|

3.Lead

forming should be performed prior to soldering.

|

| |

1.

Special

care shall be taken when applying the chemicals listed below for

cleaning

because certain chemicals may damage the surface

of l

ens

or

case

and cause discoloration.

|

4.Avoid

applying any stress to resin in order to prevent

the epoxy

fracture and break on bonding wire.

|

| |

| |

5.Avoid

Forming the lead Frame at the same point twice or more.

|

|

|

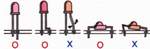

Solvent

|

Adaptability

|

|

Ethyl alcohol,

lsopropyl alcohol

|

O

|

|

Trichloroethylene,

Chlorothene

Acetone,

Thinner

|

X

|

|

|

| Soldering |

|

1.Be

sure not mount LEDs in conditions where excessive stress is applied to

lead

frames.

|

| |

|

|

|

2.Dipping

time: 2 minutes max. at normal temperature.

|

|

|

|

2.The

mounting direction of the flat package type LED should be such that

the

direction of the LED electrodes is perpendicular to the direction of

the board

curve.

|

|

|

| |

Forming |

3.Ever-Led

will not guarantee

LEDs

mounted

directly on the board because the

resin

bodies may be damaged by the applied force from board - warping,

lead-cutting

or clinching when being soldered. (

It

is

strongly recommended

that this should be carried out after very careful preparation.)

|

|

.

|

1.The

lead frame should be bent at a point 2 mm away from the body resin.

|

|

|

|

4.Care

should be taken to avoid any shock or vibration to the LED resin body

after

it has been soldered until

the temperature of the

LED

has

returned to

normal.

|

|

|

2.Bending

should be performed with the base firmly fixed by means of a jig

or

radio pliers.

|

|

|

|

5.Conditions

|

|

| |

|

Types

|

Soldering iron

|

Dip soldering

|

Reflow soldering

|

|

|

|

Temperature

at tip of iron:

|

| 300°Cmax. |

|

(300 W

max.)

|

|

soldering

time: 3 sec. max.

|

|

Location:

At least 3 mm

|

|

away from

resin body

|

|

|

|

Pre-heating: 100°C

max.(Resin

surface

|

| temperature) |

| 60 sec. max. |

| Bath temperature: 260±5°C |

| (Small package: 240±5°C |

|

Dipping time: 5 sec.

max.

|

|

Location:

At least 3.0mm away from resin body)

|

|

Not recommended

|

|

|

|

Temperature at tip

of iron:

|

| 300°Cmax. |

| (300 W max.) |

|

soldering time: 3 sec.

max.

|

|

Location: At least

2.6 mm

|

| away from resin body |

|

|

Pre-heating:

80

°Cmax.(Resin surfacetemperature)

|

| 60 sec. max. |

| Bath temperature: 260±5°C |

| (Small package: 240±5°C |

|

Dipping time: 5 sec.

max.

|

|

Location:

At least 3.0mm away from resin body)

|

|

Not recommended

|

|